In the rapidly evolving world of electronics, the demand for flexible printed circuit boards (flexible PCBs) is surging, driven by innovations across various industries. As technology trends shift toward more compact, lightweight, and adaptable solutions, flexible PCBs have emerged as a crucial component in enabling these advancements.

This blog will explore the exceptional manufacturing capabilities of top Chinese factories that specialize in flexible PCB production, highlighting not only the latest techniques and standards but also the significant implications for industry 2025. By examining the current trends and providing a "how to" guide, we aim to equip readers with the knowledge necessary to navigate the state-of-the-art in flexible PCB technology and make informed decisions that could propel their projects into the future.

This blog will explore the exceptional manufacturing capabilities of top Chinese factories that specialize in flexible PCB production, highlighting not only the latest techniques and standards but also the significant implications for industry 2025. By examining the current trends and providing a "how to" guide, we aim to equip readers with the knowledge necessary to navigate the state-of-the-art in flexible PCB technology and make informed decisions that could propel their projects into the future.

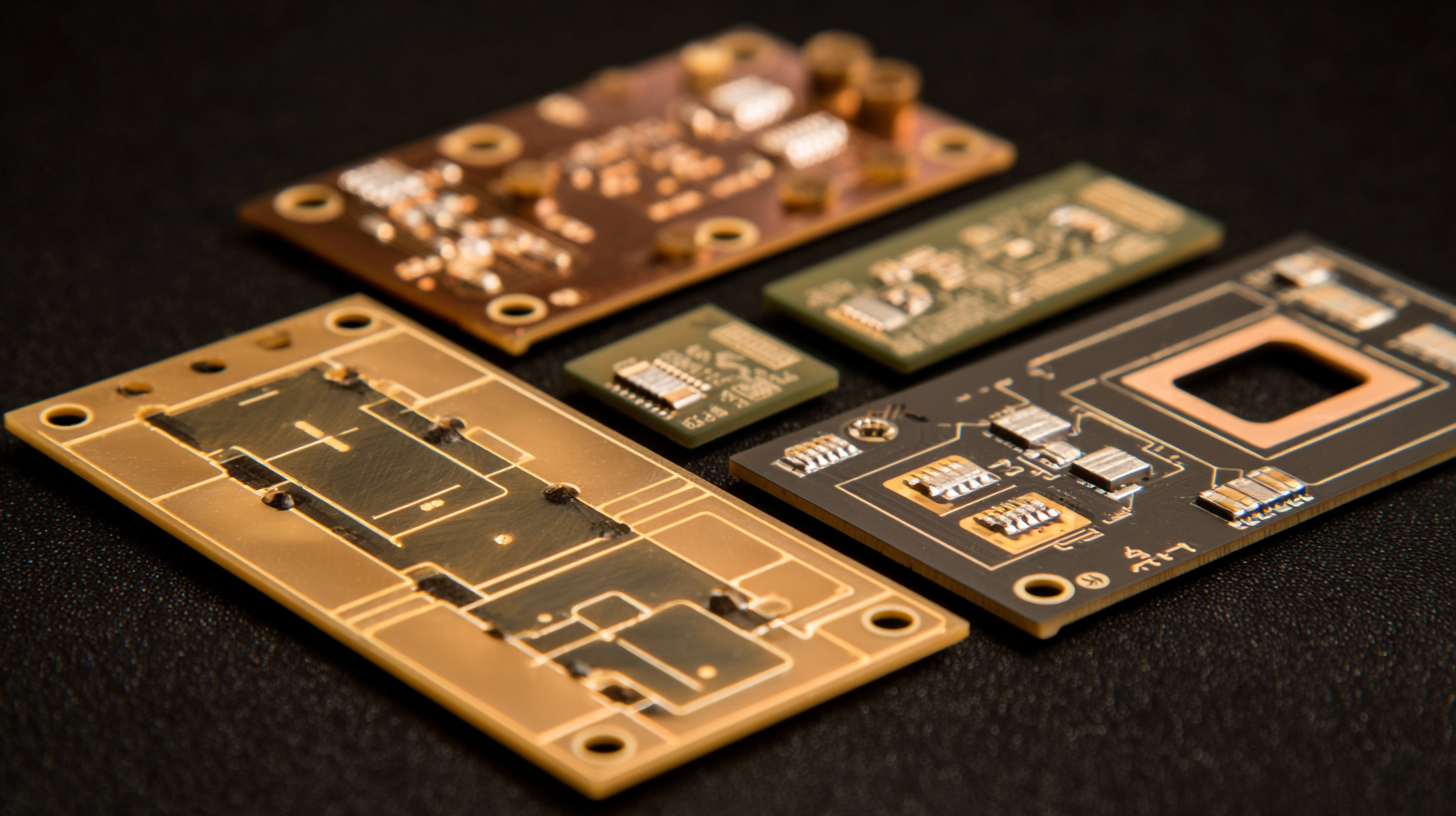

Flexible printed circuit boards (PCBs) have revolutionized the electronics industry, playing a vital role in modern devices. Their light weight and versatility allow for innovative designs that traditional rigid PCBs cannot achieve. According to a recent report by Markets and Markets, the global flexible PCB market is projected to reach $36.41 billion by 2025, driven by increasing demand in sectors such as consumer electronics, automotive, and medical devices. The ability to bend, fold, and fit into compact spaces enhances product design and functionality, making flexible PCBs indispensable in the development of cutting-edge technology.

Tips: When considering flexible PCBs for your projects, ensure compatibility with your intended designs. Evaluate the materials used—polyimide and polyester are common options that offer differing performance characteristics. Additionally, assess the thermal tolerance and durability of the components to avoid potential failures in demanding environments.

Tips: When considering flexible PCBs for your projects, ensure compatibility with your intended designs. Evaluate the materials used—polyimide and polyester are common options that offer differing performance characteristics. Additionally, assess the thermal tolerance and durability of the components to avoid potential failures in demanding environments.

Incorporating flexible PCBs not only improves device efficiency but also promotes energy savings. A study from Research and Markets highlights that the integration of flexible PCBs can reduce the overall weight of devices by 60%, consequently enhancing battery life—a critical factor in portable electronics. As the demand for lightweight and efficient technology continues to grow, flexible PCBs will undoubtedly remain at the forefront of electronic innovations.

In recent years, the demand for flexible printed circuit boards (PCBs) has surged, driven by advancements in electronics and the increasing need for compact, lightweight designs. According to a report by MarketsandMarkets, the global flexible PCB market is projected to reach USD 22.94 billion by 2025, growing at a CAGR of 10.2%. This growth underscores the importance of high-quality manufacturing practices in the production of flexible PCBs, particularly from leading manufacturers in China.

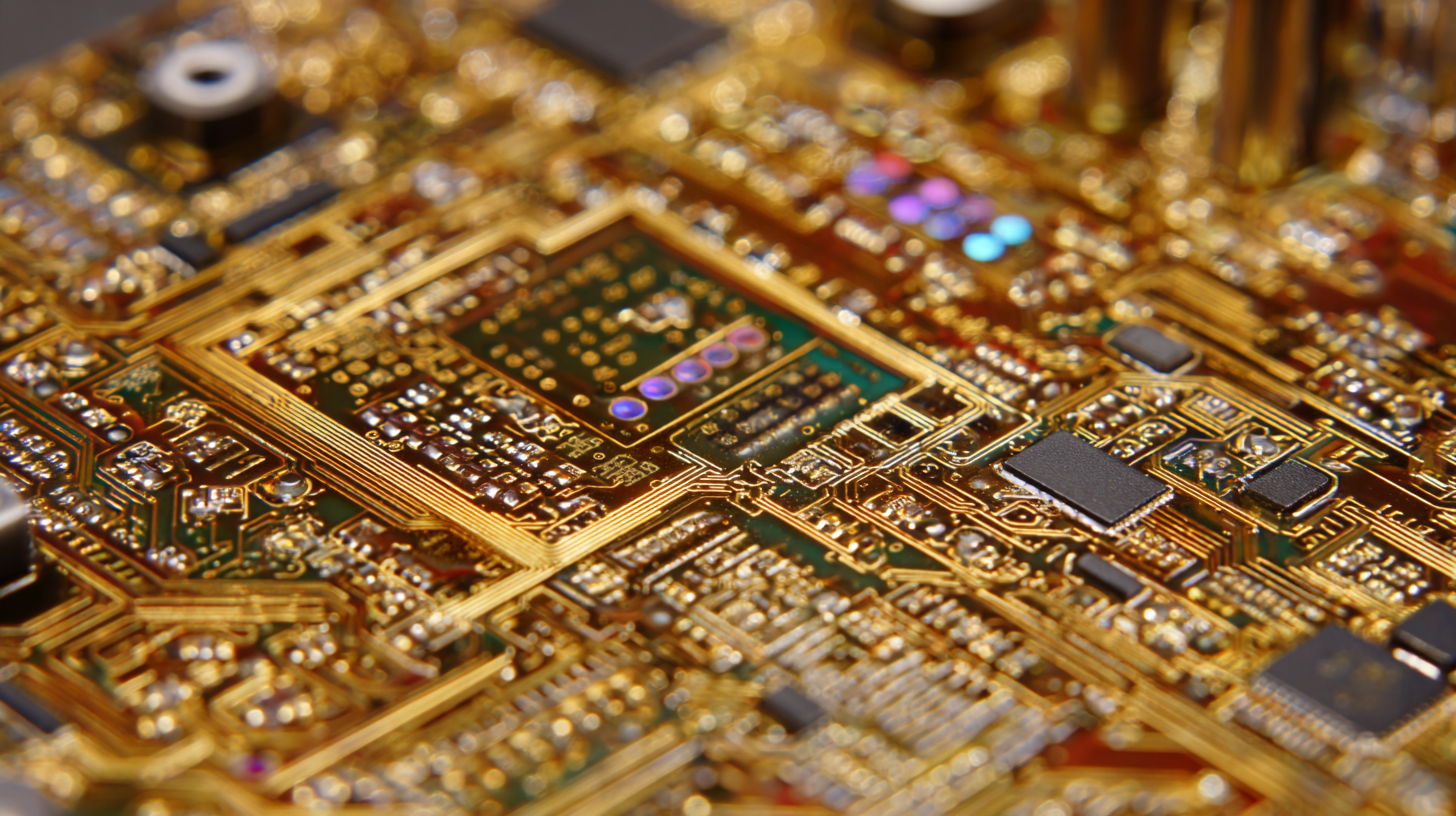

One of the key features of exceptional flexible PCBs is their ability to withstand high levels of mechanical stress without compromising performance. This characteristic is achieved through advanced materials and technologies. For instance, the use of polyimide films not only enhances flexibility but also provides excellent thermal stability. Furthermore, top manufacturers prioritize precision in their fabrication processes, employing automated technologies that ensure consistent quality and reliability. Industry reports indicate that a substantial percentage of flexible PCBs produced by leading factories meet stringent international quality standards, such as IPC-A-610 and IPC/WHMA-A-620, further solidifying their reputation in the global market.

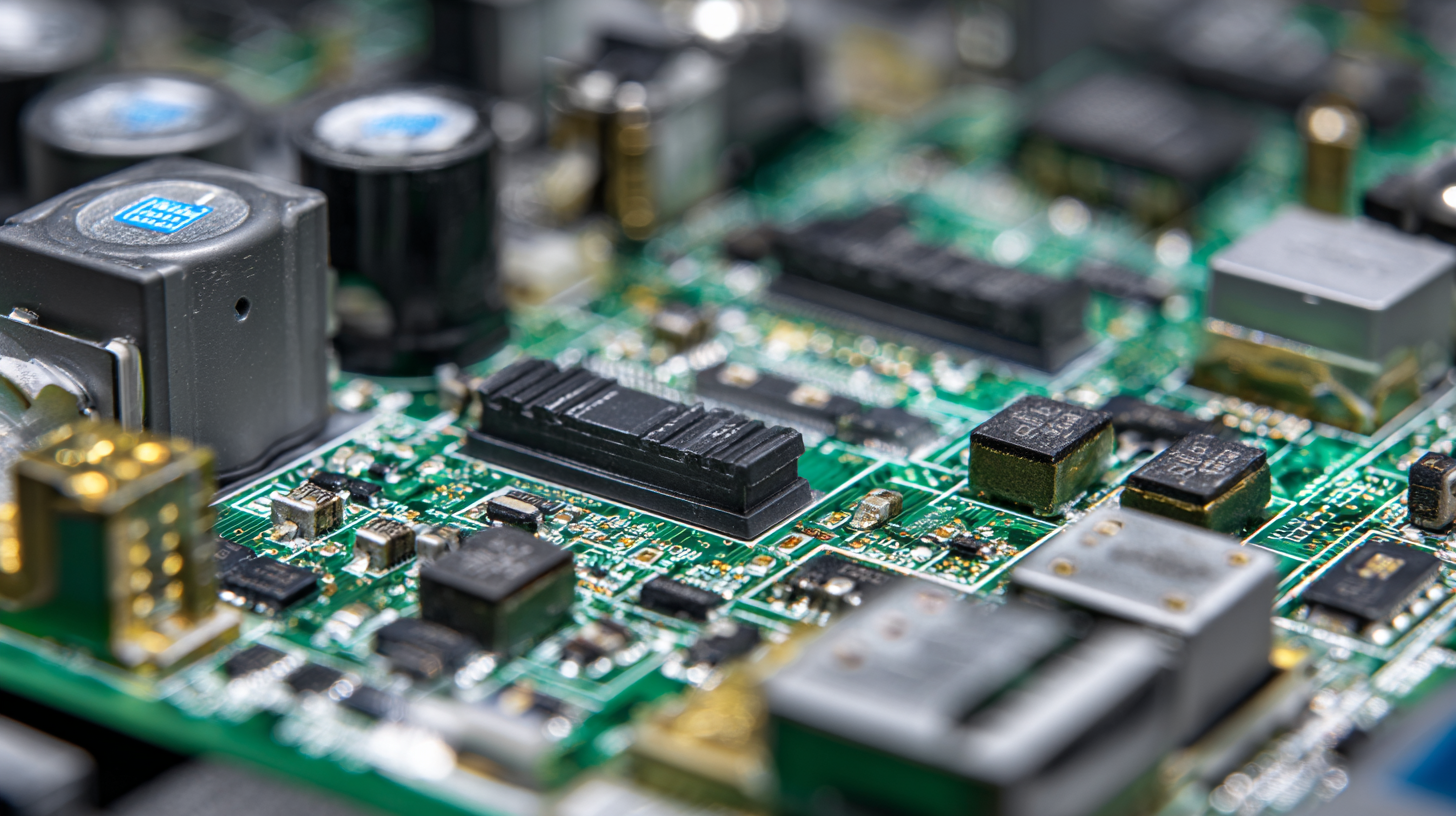

Flexible Printed Circuit Boards (FPCBs) are revolutionizing the way we approach product design and functionality. Unlike traditional rigid PCBs, flexible PCBs can bend, twist, and fold, allowing engineers to create innovative shapes that accommodate unique design requirements. This flexibility not only optimizes space but also enhances connectivity in compact devices, leading to improved overall performance.

When designing products with flexible PCBs, it’s essential to consider material selection carefully. High-quality materials with excellent dielectric properties can significantly enhance signal integrity and durability. **Tip:** Always choose materials that are tailored to your specific application to maximize efficiency. Additionally, incorporating a sufficient number of test points within the design can facilitate easier troubleshooting during the manufacturing process and ensure a reliable final product.

Another vital aspect of flexible PCB design is the layout. A well-thought-out layout can minimize crosstalk and electromagnetic interference, ultimately improving the performance of the device. **Tip:** Use simulation tools to visualize the circuit’s behavior before finalizing the layout. This foresight can prevent costly revisions and ensure the optimal functionality of your product.

In recent years, flexible printed circuit boards (PCBs) have gained immense popularity due to their cost-effectiveness and versatility in various applications. Recent data highlights that the global flexible PCB market is expected to exceed USD 25 billion by 2025, driven by increasing demand in sectors such as consumer electronics, automotive, and medical devices. This trend is particularly relevant in the context of Southeast Asia, where significant investments in PCB manufacturing are being made.

For instance, two major PCB projects in Southeast Asia have recently reported advancements, with investments totaling over USD 8 billion. These projects indicate a growing trend in the industry where manufacturers are gradually shifting towards flexible PCBs due to their lightweight and space-saving characteristics. Flexible PCBs not only reduce the overall cost of production but also offer enhanced performance, making them ideal for high-density interconnect applications. As more companies adopt flexible PCB technology, the cost-effectiveness becomes increasingly apparent, presenting a lucrative opportunity for businesses looking to innovate and cut costs simultaneously.

| Attribute | Value |

|---|---|

| Material Type | Polyimide (PI) |

| Layer Count | 1-6 Layers |

| Thickness | 0.1 mm to 0.5 mm |

| Minimum Traces / Spaces | 3/3 mil |

| Copper Foil Thickness | 1 oz to 2 oz (35µm to 70µm) |

| Production Capacity | 100,000 sq. ft./month |

| Lead Time | 2-4 weeks |

| Cost per unit | $0.20 - $1.50 |

| Testing Methods | Visual inspection, Electrical testing |

| Applications | Consumer Electronics, Medical Devices, Automotive |

In the realm of flexible PCB manufacturing, ensuring reliability and safety is paramount. The processes involved in creating high-performance flexible PCBs must adhere to rigorous standards that guarantee the end product can withstand the demanding environments of various applications, from consumer electronics to automotive systems. With the rising demand for advanced electronics, manufacturers are employing state-of-the-art technologies and methodologies to enhance the safety and dependability of their flexible circuits.

One key aspect of achieving reliability in flexible PCB production is strict quality control throughout the manufacturing process. Utilizing automated inspection methods, such as machine vision systems, allows for real-time monitoring and immediate detection of defects. This technology not only minimizes human error but also optimizes production efficiency and quality assurance, leading to safer end products. As the flexible PCB market evolves, integrating such innovations will be vital for manufacturers aiming to meet the ever-increasing expectations of both safety and performance in their offerings.

Address :

Absolute Electronics Services LLC

330 W Fay Ave

Addison, IL – 60101

2025 Absolute Electronics Services, All Rights Reserved